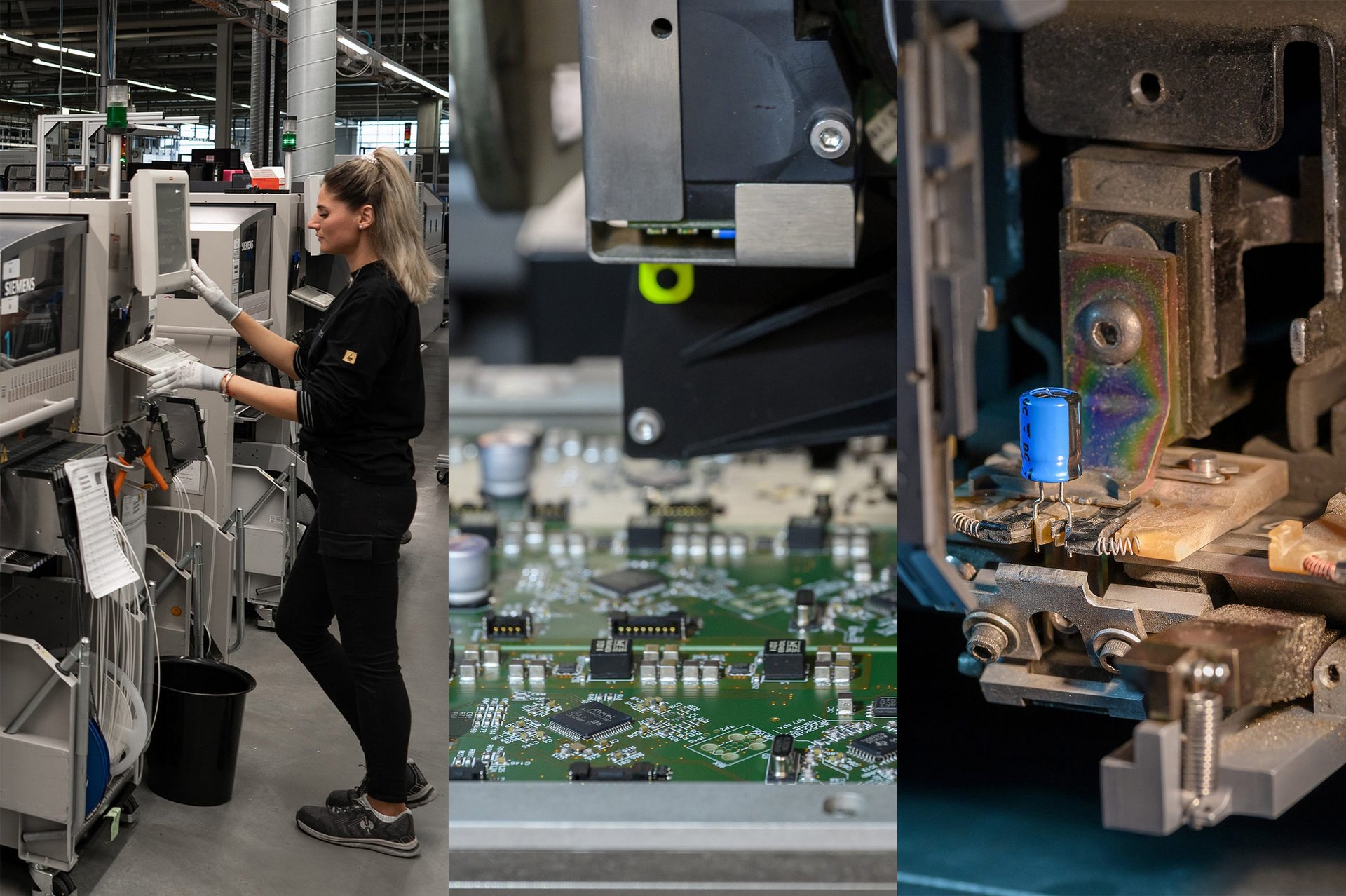

THT assembly

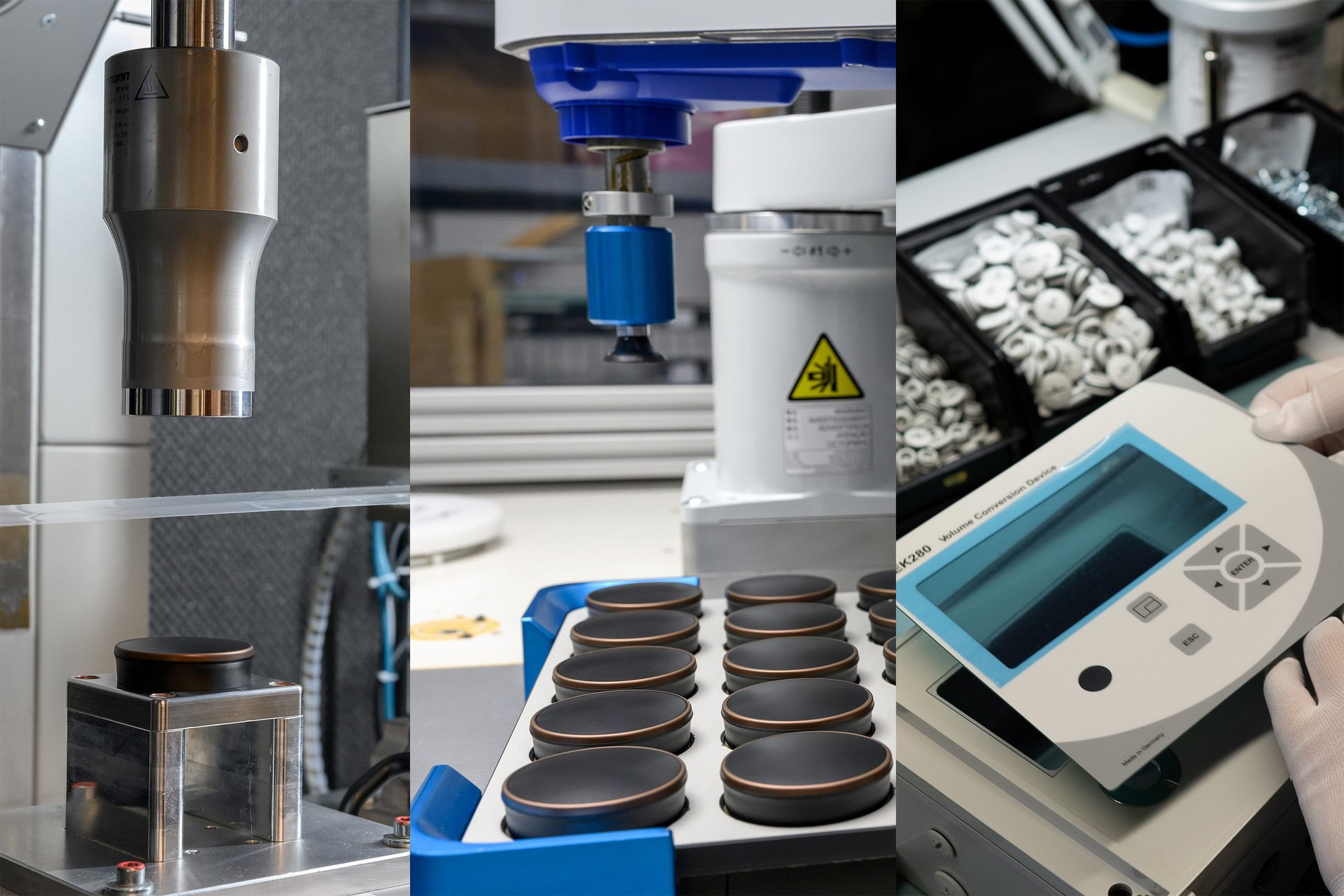

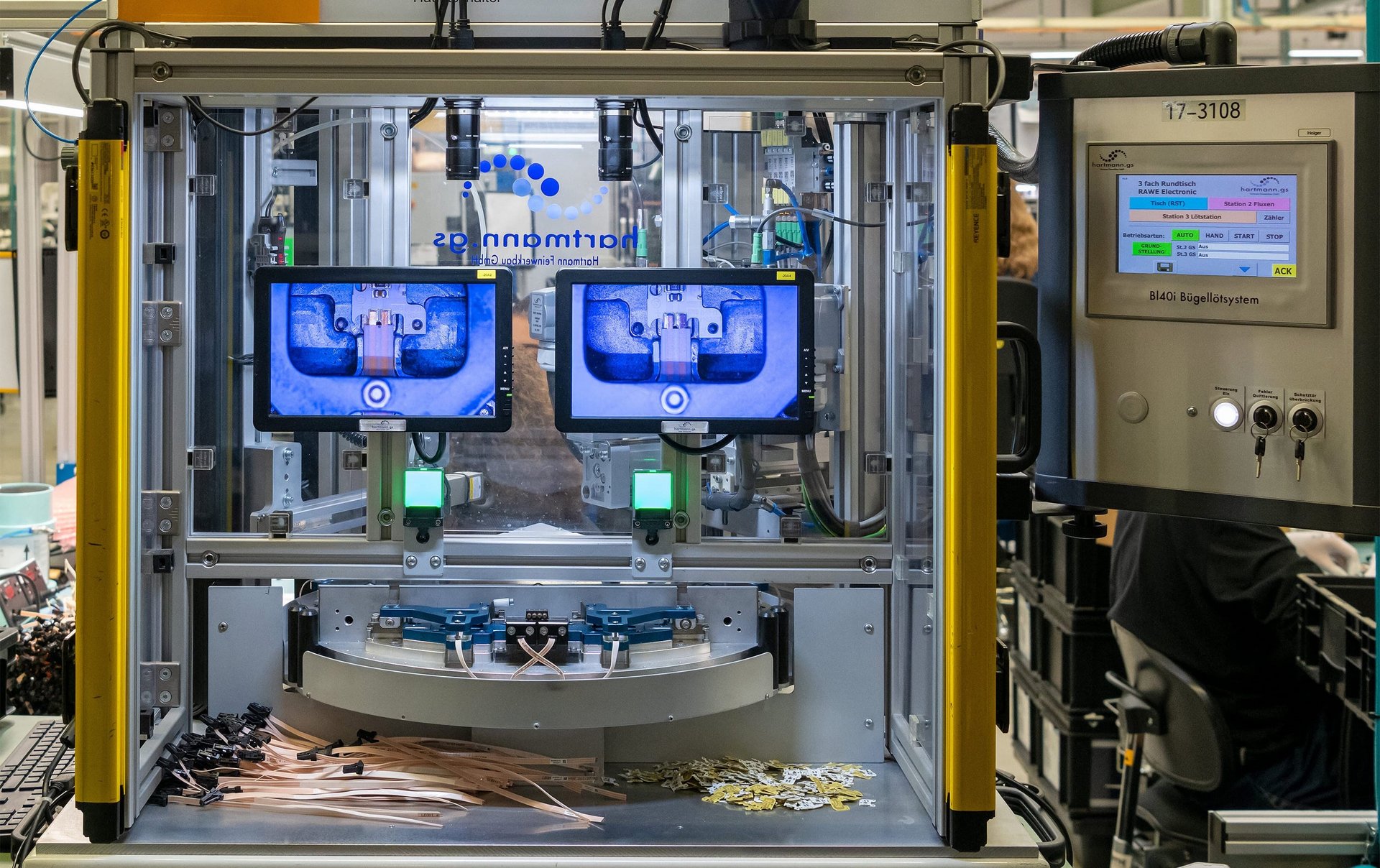

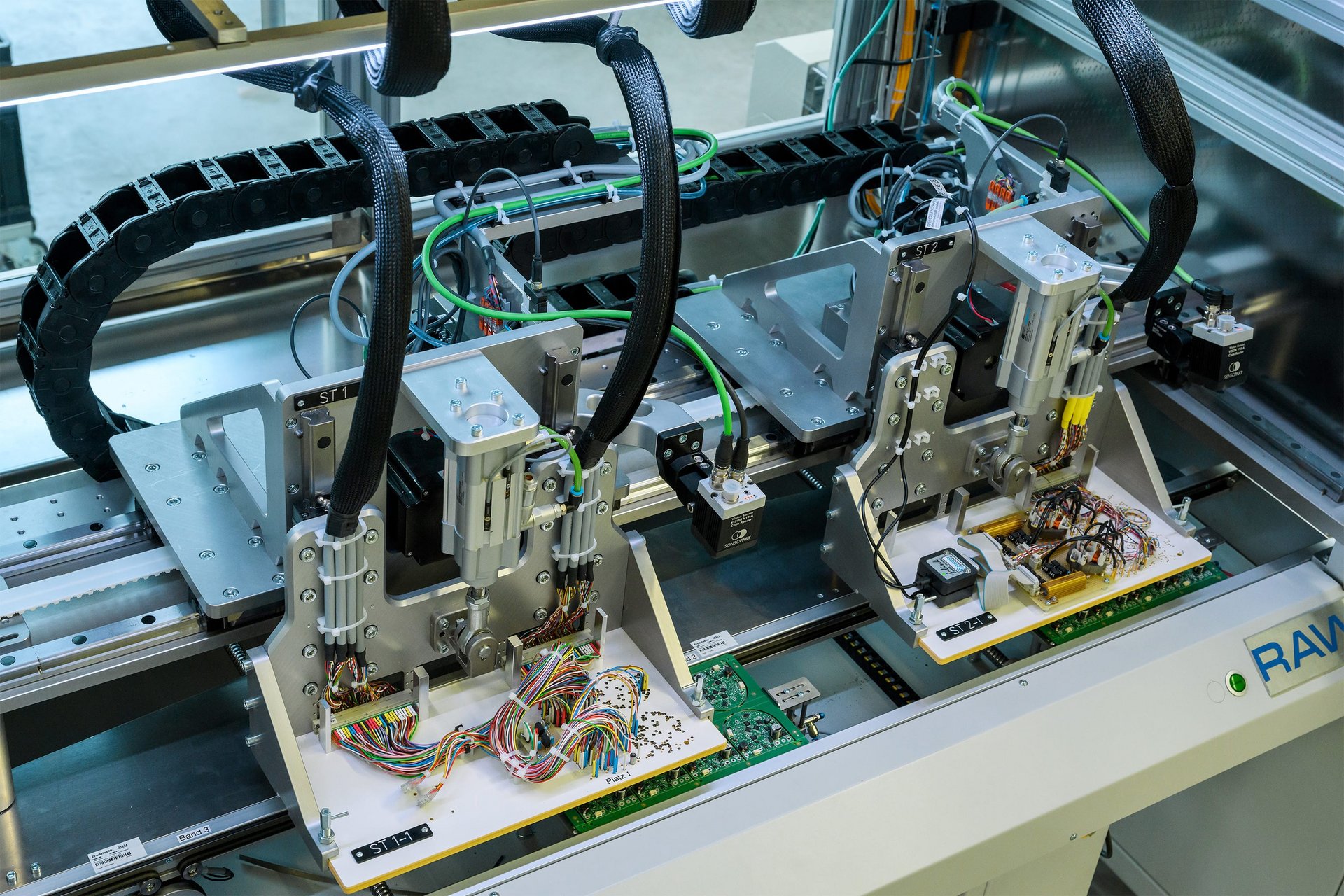

THT (through-hole technology) is carried out either automatically or manually. We can assemble the following housing types automatically:

- Dual inline package (DIP) RM 2.5 in 3/10 package

- RM 5 radial housing

- Axial THT housing

The assembly of large components as well as connection cables or heat sinks is usually done manually.