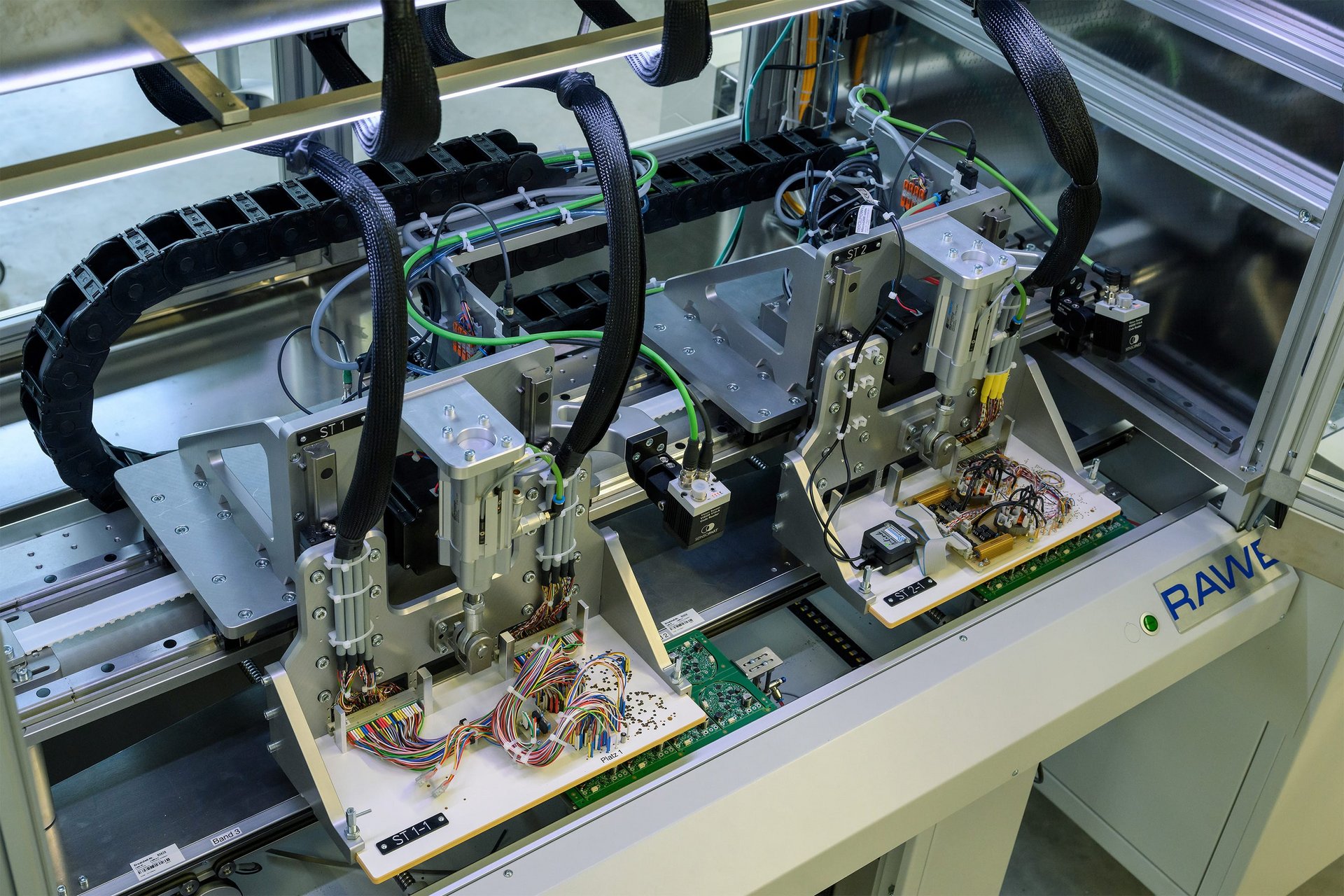

Integrated Placement Control

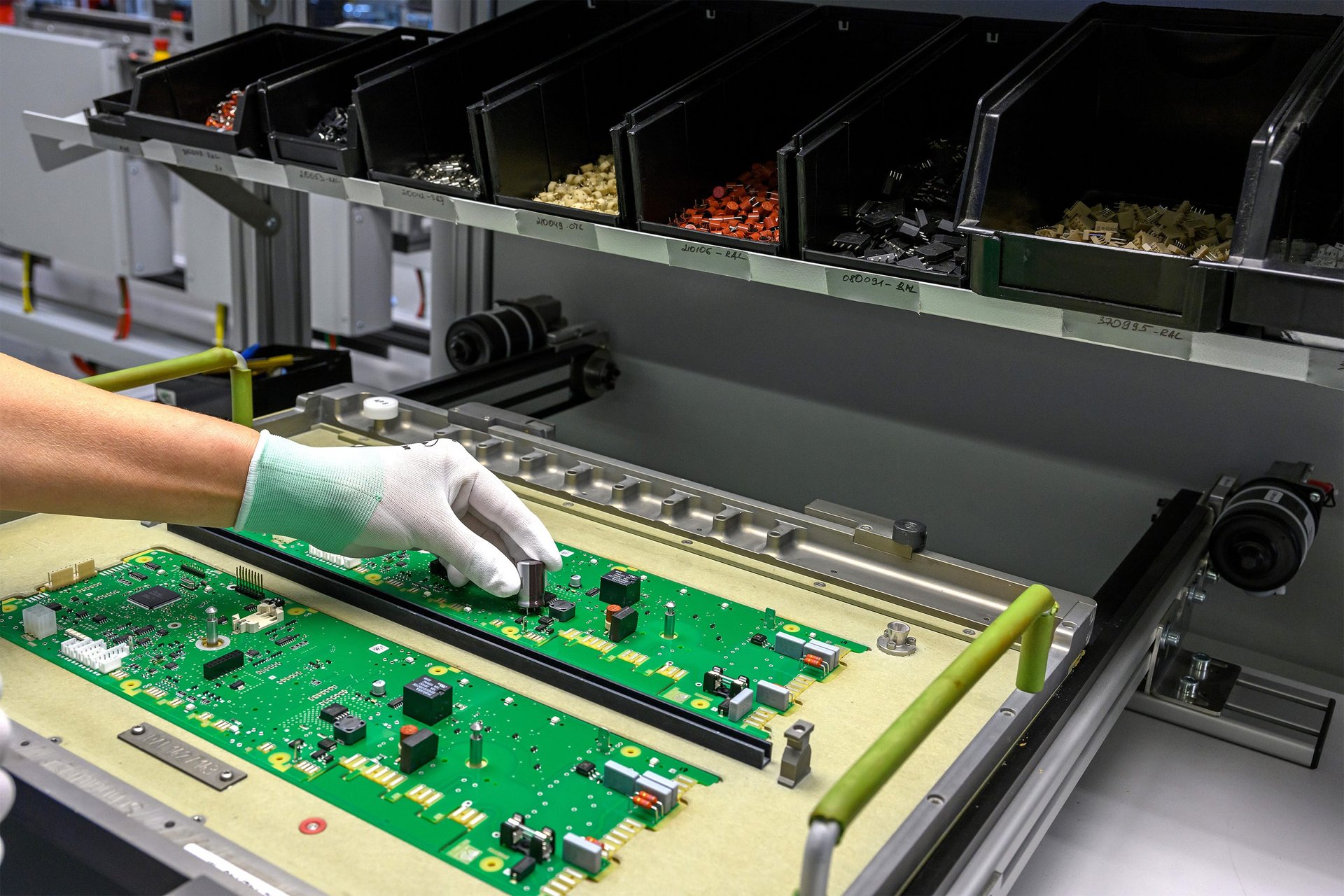

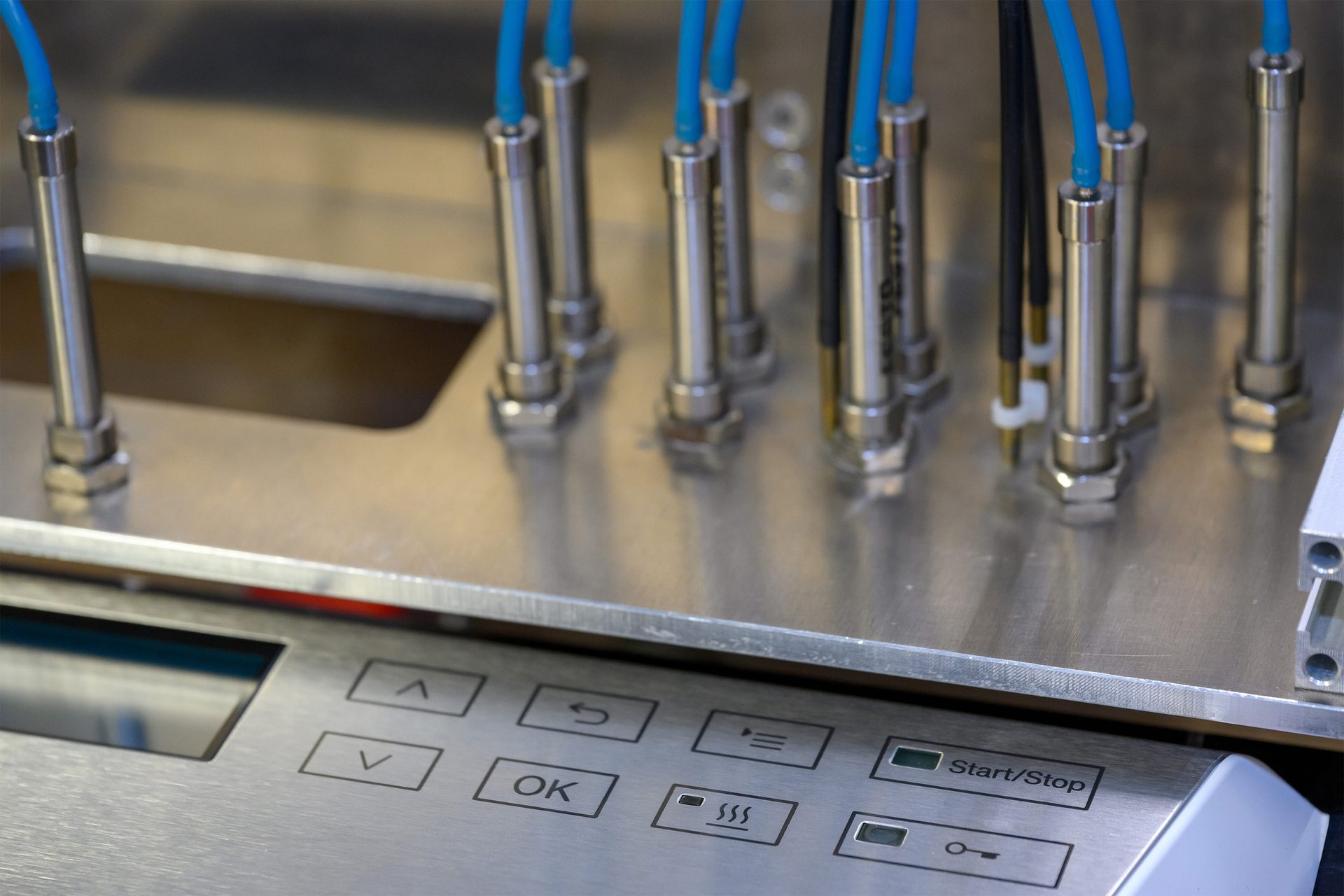

A fully integrated placement check, which is connected upstream of the wave soldering process, ensures that all manually placed components are positioned correctly and without errors. The test system is integrated into the handling and transport system and guarantees a smooth process flow.